In the field of municipal or industrial wastewater treatment, sludge is naturally generated from the growth of microorganisms. The classic sewage treatment process relies on the microorganisms in sludge to absorb and decompose various toxic and harmful pollutants. This process generates harmless carbon dioxide, water and more microbial sludge. This part of biological sludge is called “activated sludge.” In order to maintain balance in the system, it is necessary to regularly discharge sludge. This “excess sludge” must be dewatered and disposed of according to requirements established by regional authorities.

Worldwide sludge production is extensive and growing. In Europe alone, sewage treatment plants produce an average of 22.5 kg dry matter of sludge per capita per year [1]. Given Europe’s population of 750 million people, this equates to 17 million tons of dry sludge per year. As sludge production increases and regulations evolve, municipalities and industrial operations are looking for more efficient methods of sludge disposal.

Changing Regulations

Sewage sludge contains heavy metals and pathogens, such as viruses and bacteria. It also contains valuable organic matter and nutrients, such as nitrogen and phosphorus. It can therefore be very useful as a fertilizer or soil enhancer.

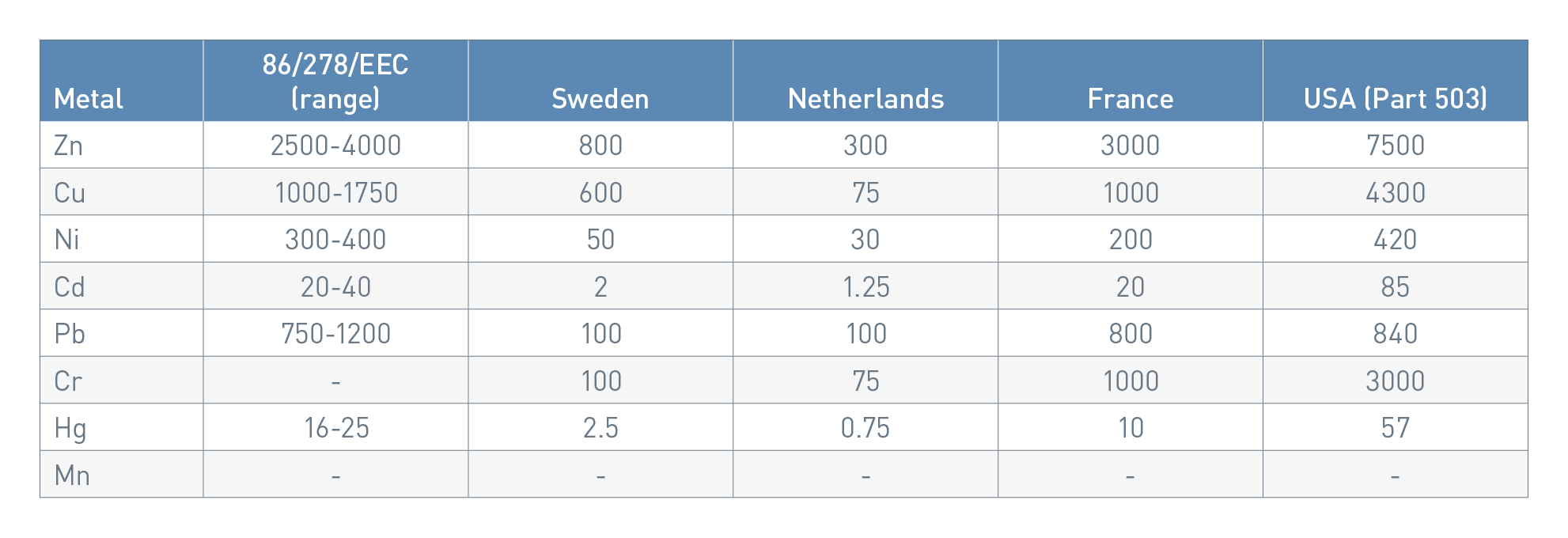

For these reasons, European Union (EU) rules promote the use of sewage sludge in agriculture but regulate its use to prevent harmful effects on soil, vegetation, animals and people. Specifically, EU Directive 86/278/EEC prohibits the use of sludge in agriculture if heavy metal concentrations exceed defined values, but it sets no limits for organic contaminants (Table 1) [2].

TABLE 1. Maximum permissible limits for land application, EU, US and National Legislation (mg/kg d.w.).

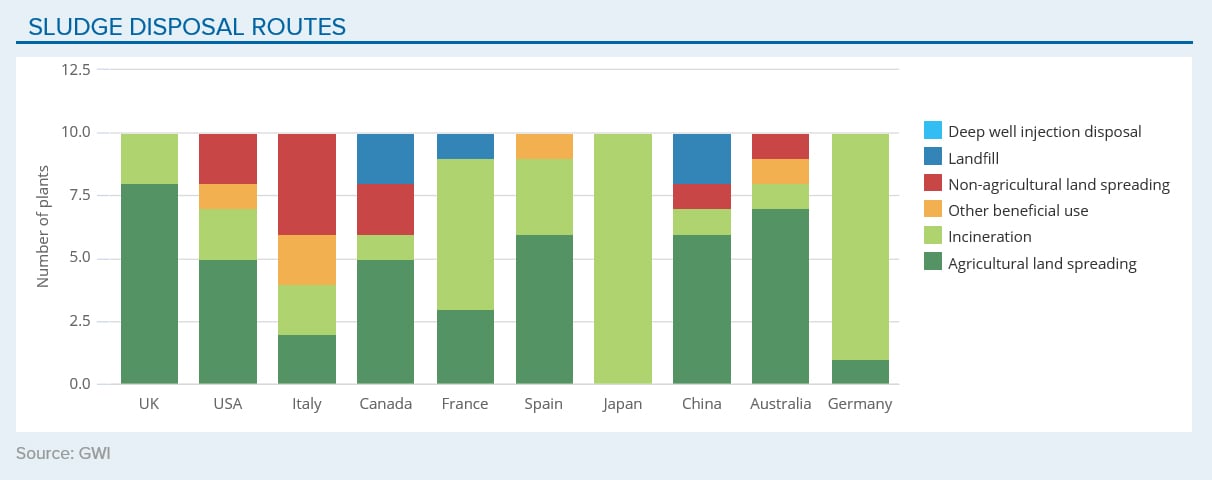

In most cases, the limits set by individual countries vary considerably, though they are significantly lower than the requirements of the EU Directive 86/278/EEC. This variation is due to, among other factors, the type and intensity of each country’s agricultural systems. The Netherlands, for example, is a relatively small country with intensive land use and high agricultural output. Therefore, the heavy metal limits are set so low that agricultural application of sewage sludge is not feasible. As a result, 100 percent of the municipal sludge in the Netherlands is incinerated. In other countries, this is not the case. Figure 1 shows the sludge disposal methods used at the 10 largest municipal wastewater treatment plants in various countries.

Figure 1. Sludge disposal routes in various countries. [3]

All sludge is incinerated in Japan. The incineration rate is 90 percent in Germany, 60 percent in France, and 20 percent in the United States and the United Kingdom. The megatrend is towards incineration, increasing the overall disposal cost. The cost for incineration is approximately $90 to $130 per metric ton, significantly more than the landfilling cost of $40 to $70 per metric ton.

Dewatering and Disposal

The efficiency of sludge disposal is directly related to dewatering, the process by which sludge is separated into liquids and solids. This separation is key to reducing the sludge weight and volume, which reduces transportation and disposal costs and ultimately improves the sustainability of a wastewater treatment operation.

The three most common processes for dewatering involve filter presses, centrifugation, and belt presses. Filter presses use a cloth filter and high pressure to separate solids and liquids; centrifuges use centrifugal force to separate materials by density; and belt presses use gravity to separate free water molecules before the remaining sludge is squeezed between two rolling belt filters.

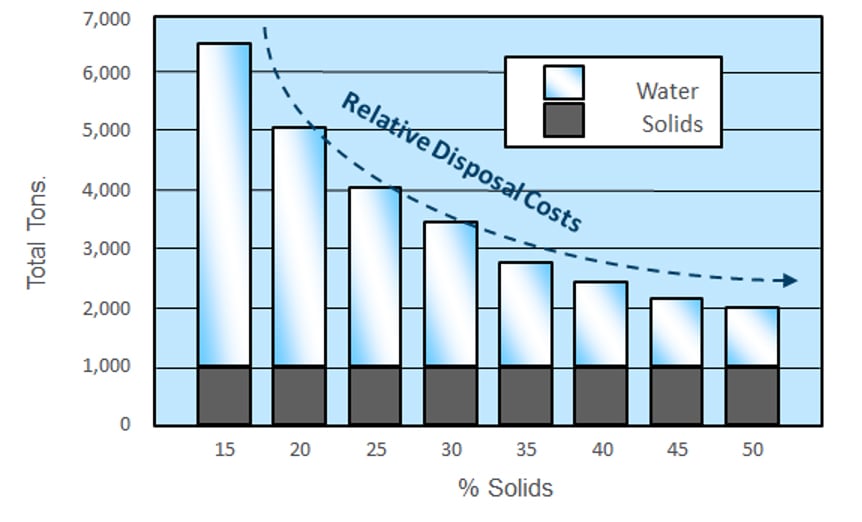

Even after dewatering, sewage sludge has a water content of around 75 to 80 percent. This means the sludge has a cake dryness (solids content) of 20 to 25 percent. The higher the water content in sludge, the higher the disposal and incineration costs.

The Solenis Solution

Flocculants are chemicals used in sludge dewatering operations to increase the dewaterability of the sludge. They work by causing small particles present in the sludge to agglomerate into larger flocs. Specially designed products and specific dosages maximize this process and reduce disposal costs by minimizing sludge water content.

Solenis helps global municipal and industrial treatment plants improve the efficiency of dewatering processes with its Zetag™ and Praestol™ flocculants, making it possible to reduce water content in the sludge and, as a result, the overall disposal cost.

By increasing cake dryness, Solenis products help treatment plants gain significant savings. A municipal treatment plant serving 5 million people will save $5.8 million per year by increasing cake dryness from 20 percent to 25 percent with disposal costs of $65 per ton (see Figure 2).

Figure 2. Impact of cake dryness on relative disposal cost.

Our flocculants are just part of a large portfolio of solutions designed for the municipal market. To learn more or to discuss how we can help your operation reduce its sewage sludge disposal costs, visit Solenis.com.

References

[1] Bianchini, A., Bonfiglioli, L., Pellegrini, M. and Saccani, C. (2016). Sewage sludge management in Europe: a critical analysis of data quality. International Journal of Environment and Waste Management. 18. 226. 10.1504/IJEWM.2016.10001645.

[2] Inglezakis, V., Karagiannidis, A., Samaras, P. and Zorpas, A. (2014). European Union legislation on sewage sludge management. Fresenius Environmental Bulletin. 23. 635-639.

[3] Global Water Intelligence. (2021). Sludge Management.