The Paper and Materials Testing Services group, which is a key element of our Customer Applications Laboratories, works closely with our sales, applications and research teams to understand the desired structural properties of our customers’ products and to assist in the development of treatment technologies that address current and future customer needs. This experienced group of scientists and technicians leverages state-of-the-art testing equipment and methods to evaluate the performance of a variety of paper and non-paper products for customers. The information gained from these evaluations is ultimately used to help customers optimize the functional properties of their products using proven chemical solutions.

With laboratories strategically located around the world, the Paper and Materials Testing Services group can help customers, wherever they may be based, meet their product quality and sustainability goals.

Packaging

Packaging covers a wide range of products and is an important component of our global economy. Packaging materials made from paper products help keep shipping costs down and accessibility high.

Structural Integrity

Structural strength is important to maintaining high-quality packaging of goods being transported. Our strength testing is used to maximize a package’s resistance to crush and internal failure when stacked, stressed or shipped/stored in challenging environments such as high temperature or humidity.

- Stiffness, in-plane and deflection

- Crush resistance on flat, folded or molded fiber structures (from edges to boxes to egg cartons)

- Puncture and tear resistance

- Internal bond and delamination strength

Anti-Slip

A component of safe shipping both for the goods and people involved.

- Comprehensive frictional analysis (static and dynamic coefficient of friction, slide angel, abrasion resistance)

Sizing and Barrier Applications

Solenis has testing capabilities to determine surface and internal sizing for a wide range of materials both aqueous and aliphatic. We have designed specialized testing capabilities to evaluate food and liquid packaging products, two of the most engineered grades in the market today.

- A comprehensive range of edgewick evaluations with the expertise to match (solo, video microscopy, failure analysis)

- Timed and conditioned penetration studies to determine a packaging material’s resistance to specific materials (pet food, oils/greases, customer specified)

- Transport phenomenon for moisture and oxygen permeable materials

Tissue

The use of tissue products continues to expand with globalization and improvement in the quality of life across the world. Tissue products offer some of the most complicated properties that Solenis is well suited for with the combination of our expertise, testing capabilities and tissue innovation center.

Strength

Tissue products have a wide range of strength requirements. These include dry strength for processibility, permanent wet strength for towels, and temporary wet strength for bath and specialized products.

- Tensile, ball burst, drapability

- Linting and debonding strength

- Dispersibility

Softness

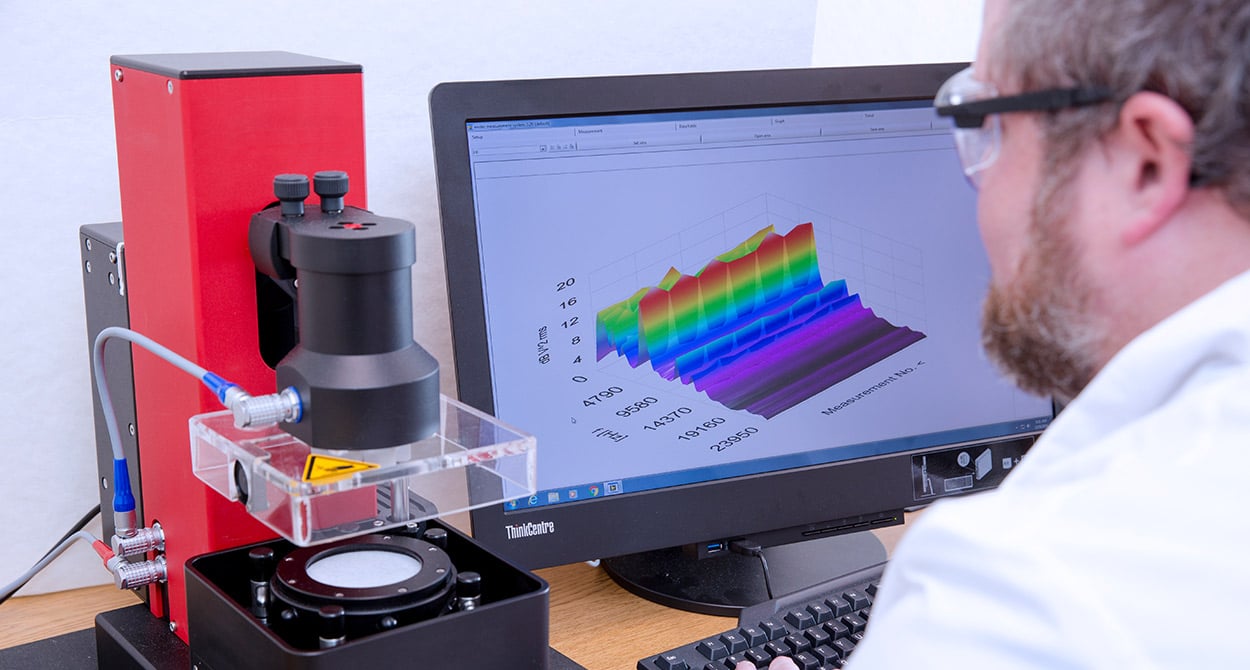

Softness determination is a non-trivial task. Solenis has a wide range of capabilities to evaluate softness from its most basic components to complex algorithms and human sensory panels.

- Tissue softness analyzer that can be adjusted to specific product and regional specifications

- Trained and qualified hand-feel panels

- Handle-o-meter

- Friction analysis

- Specialized testing available at our tissue innovation center

Fluff Pulp

Fluff pulp goes into a wide range of products for adsorption of liquids. We have the tools needed to evaluate the processability of current lines as well as assist in feasibility studies for converting an existing pulp line to fluff pulp.

- Hammermill energy consumption

- Debonding Strength

- Absorption rate and capacity

- Static potential

Graphic and Specialty Papers

The written or printed word is a strong form of communication even in this modern age. Products from magazines and journals to reports and memos are widely used tools for marketing, scientific progress and enjoyment. We have specialized tests to optimize or evaluate printed material.

Printability

The forefront for evaluating graphic and specialty papers is printability. Good printability is a balance between sizing, paper structure, and absorption or compatibility of inks and toners.

Problems on the production line? Package them up and send them to us.

- Color, brightness and sheet opaqueness analysis (color mapping, density, mottle, fluorescence)

- Ink compatibility (dynamic contact angle, runnability, toner adhesion)

- Surface and structural properties (smoothness, porosity)

- Image analysis (feathering, dot circularity, ink to ink compatibility)

- A range of techniques for determining paper formation

- Latest and industry standard capabilities for determining sizing of all types of paper products

Processability

A quality image is only useful if the paper media possesses the structural properties to make it through a printer. Everything from high-speed industrial offset to office and home toner and inkjet printers.

- Stiffness

- Tear

- Tensile

- Coefficient of friction and slide angle

We have the experience to investigate the quality of many specialty grades of paper, including anti-sceptic, building materials, filters, wrapping, insulating, layered materials, roofing and gypsum board.

Non-Paper Products

To support our non-paper customers, we are constantly growing our capabilities and expertise. A few examples where we have

capabilities in this area are building materials, plastics, elastomers and well caps for mining operations.

Quality Testing and Method Verification

We participate in several programs to ensure the results and analyses we provide are accurate and up to date.

- Internal collaborative testing between all Solenis Regional laboratories

- External collaborative testing with non-Solenis paper and material testing laboratories

- Within each lab many of our instruments are duplicated, allowing for immediate comparison

- Regular method reviews and technician training to ensure we are providing the most accurate data possible

- Annual preventative maintenance and calibration by equipment suppliers and professionals