The Papermaking Support group, which is a key element of our Customer Applications Laboratories, works closely with our sales, applications and research teams to understand our customers’ manufacturing challenges and to assist in the development of treatment technologies that address current and future customer needs. This experienced group of scientists and technicians possesses extensive knowledge of various pulp and papermaking processes and wet-end chemistries and applies this knowledge to provide customers with problem-solving treatment strategy recommendations leveraging state-of-the-art process simulation tools and methods.

With laboratories strategically located around the world, the Papermaking Support group can help customers, wherever they may be based, meet their productivity, product quality and sustainability goals.

Retention and Drainage

A thorough understanding of pulp, wet-end chemistry, additives and operating conditions allows for the optimization of retention and drainage/dewatering programs, leading to improved machine efficiency and product quality.

Simulations used to recommend an optimal treatment strategy (single, dual and microparticle polymer programs) for retention and drainage improvements include:

- Drainage and dewatering via standard methods (Schopper-Riegler and Canadian Standard Freeness) and our unique Total Dewatering testing to simulate the paper and board machine water removal process, including pressing and drying to define total energy consumption in the dryer section

- Retention, drainage and formation via vacuum-assisted Dynamic Drainage Analyzer that simulates suction boxes and primary formation

- Retention and free drainage analysis using BTG Drainage Freeness Retention (DFR) tester

For higher ash grades, Solenis offers an advanced program for improved filler retention that relies on pretreatment of the fillers. Precise testing of viscosity, particle size, slurry pumpability and retention are critical to the success of these programs.

Contaminant Control

The use of lower quality fibers and the industrial trend to close water loops has increased the potential for deposition throughout papermaking processes. Solenis strategies are based on a comprehensive understanding of these processes and the composition of contaminants to:

- Minimize paper machine downtime for cleaning

- Improve lifetime and functionality of fabrics

- Ensure consistent paper quality

Unique techniques used to recommend customized treatments include:

- System surveys, including count/particle size distribution/area, image and charge analysis

- Determination of potential depositing/agglomerating material through particle size and characteristics using modern technologies like flow cytometry

- Evaluation of stock fixatives, dispersant and detackifier programs combined with process parameter documentation

- Fabric/felt cleaning, conditioning, starch content and damage studies on single point or cross machine profiles

- Dryer Section Passivation peel tests simulating drying cylinder and dryer fabric product performance tests and their persistency towards contaminants

- Identification of microbiological contaminant sources, including subsequent biocide screenings

Repulping and Deinking

The widespread use of recycled fibers and the drive to use cheaper lower quality raw materials has stimulated the demand for improved deinking and recycled fiber recovery. Techniques used to recommend treatment strategies include:

- Stock preparation, valid for all paper grades

- Deinking with both flotation and washing technologies

- Benchtop repulping for broke and recycled processing

- Tissue dispersibility (flushability) for determining impact on municipal waste streams

Our evaluations are based on established TAPPI (Technical Association of the Pulp and Paper Industry), INDA (Association of the Nonwoven Fabrics Industry) and INGEDE (International Association of the Deinking Industry) methods for fiber yield, optical sheet properties and dirt count.

Foam Control

Foam and entrained air can cause severe operational problems. Using a variety of test methods and systems, Solenis can identify the right foam control product and ideal dosage based on performance and application parameters, while considering compatibility and compliance with relevant regulations.

Papermaking Capabilities

Solenis has established model paper making systems to predict commercial paper machine performance and to provide sales service to papermakers. Customers can evaluate products in a real-world system without jeopardizing actual machine time, cost or production. Evaluations can be done with standard market pulps or customers can supply their own pulp and process water.

The papermaking capabilities are meant for new product introduction, supporting our functional chemistry applications (colorants, sizing, surface sizing, barriers, tissue, wet and dry strength) in all market segments and customer troubleshooting. In addition, we have the expertise to assist with developing new grades.

Pilot Paper Machine

Our pilot papermaking system includes a Fourdrinier paper machine with an online film/puddle size press along with a variety of preparation and dosing equipment. Our process water and stock preparation equipment simulates real machine conditions.

Pilot paper machine specifications:

- Basis weight range 20 to 400 g/m2 with adjustable MD/CD ratios through table setup

- Multiple conditions (up to 30 per day) can be produced due to a rapid response to wet-end chemical changes

- Controlled by a modern DeltaV system with a data historian

Off-machine paper-testing enables fast expectancy of results, permitting execution of iterative test programs on the fly. The pilot paper machine correlates strongly with real work processes.

Pilot Thermoformed Molded Fiber Machine

Our new Kiefel Nature Former produces molded fiber parts using a three-stage forming process: suction, pre-press dewatering and hot pressing.

- 100 L Stock system that shares pulp preparation processes with our pilot paper machine

- Holding times, temperatures (up to 250° C) and pressures (up to 20,000 N) are fully adjustable for each stage

Hand Sheets and Size Presses

Our unique Dynamic Sheet Former (DSF) can produce sheets with basis weights ranging from 20 to 200 gsm, simulate high-shear papermaking conditions, and control machine and cross directionality. Multi-ply sheets can also be produced.

For standard benchtop hand sheet making we use a Noble & Wood former, which includes:

- A proportioner for consistent hand sheets within a set

- 8” x 8” deckle for forming sheets

- Vacuum assisted drainage for controlled dewater with the ability to reuse process water for closed cycle evaluations

- A felted press

- And a drum dryer

The DSF is used extensively for comparative studies for wet and dry strength performance as well as for fiber choice evaluations.

Increasing demand for print quality, alternative packaging and paper performance are driving the need for improved sheet surface and barrier properties. Bench size presses and a Dixon coater are available for studies of:

- Surface and sizing additives, including barrier coatings, using customers furnish or base paper as substrate

- Impact of surface-applied additives on surface strength, printability and other sheet properties

Special Tissue Simulations

Solenis laboratories offer unique capabilities for predictive modelling and simulation of tissue and towel manufacturing and converting processes, including:

- Yankee dryer process coating simulations and its impact on key functional parameters for tissue such as strength, softness and absorbency

- Tissue lotion testing facilities assisting customers seeking market differentiation to fully test lotions and topical treatments before introduction

Some of the techniques used to recommend potential treatment strategies for tissue are:

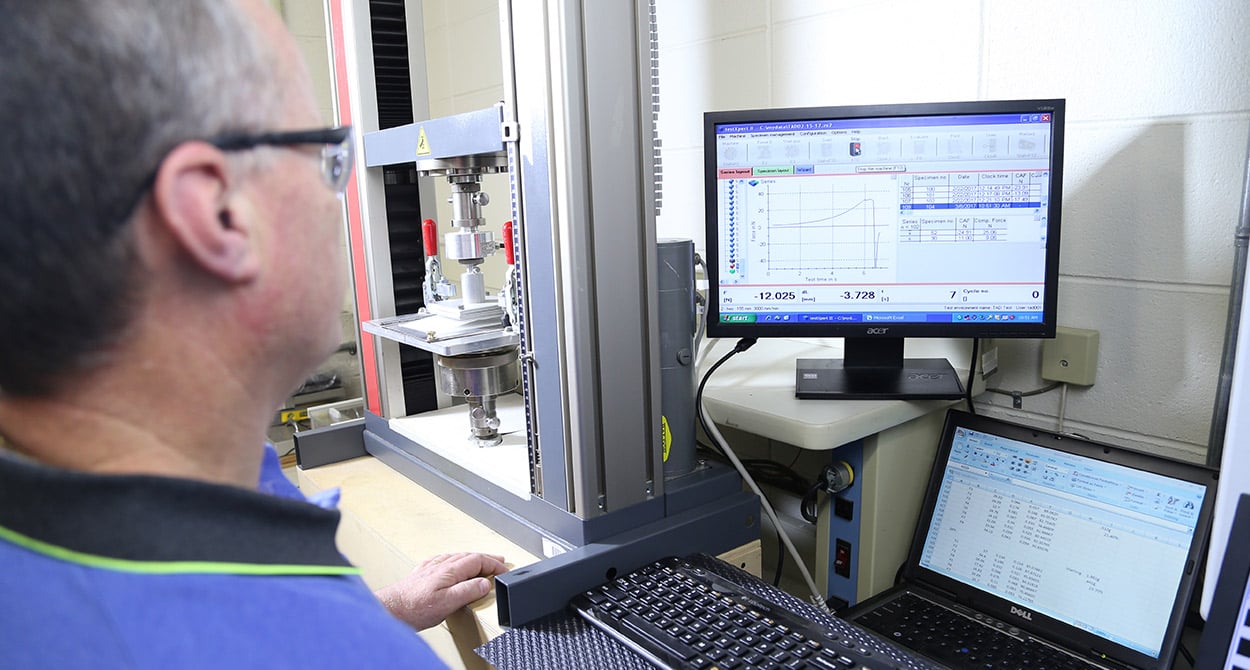

- Adhesion and Release Tester (ART)/Creping Adhesion Tester (CAT) for evaluating the adhesive properties of Yankee coatings and how the coating adhesion is affected by factors such as furnish types, internal additives, sheet moisture and Yankee temperature

- High-speed creping simulation to mimic the creping process under dynamic real-world conditions of speed, allowing measurement of final tissue properties (crepe count, softness, stretch, tensile)

- Peel testing, evaluating the impact of release agents in the Yankee coating formulations

- Dynamic Through Air Dried (TAD) simulator assessing the impact of the TAD fabric release agents and subsequently the unique sheet transfer/release from the structured fabric to the Yankee dryer

- Tissue Lotion Testing for lotions, including hot-melt waxes and ready-to-use liquids applied by spraying. Single and multilayer tissue can be treated. Sensory panel hand feel testing and instrumental softness testing compliment the physical property testing.