Water management is crucial to water-intensive industrial operations because it has an enormous impact on the performance, reliability, profitability and sustainability of these operations. The Water Applications Testing Services group, which is a key element of our Customer Applications Laboratories, understands the challenges faced by customers that rely heavily on water and has amassed extensive knowledge around industrial boiler, heating and cooling systems as well as the various processes used by heavy and light industrial operations. The technical expertise and insights provided by the Water Applications Testing Services group enable our field representatives to prescribe the ideal treatment to address a customer’s particular challenge and our R&D team to develop new-to-the-world technologies.

The Water Applications Testing Services group support customers worldwide from laboratories strategically located around the globe. These facilities house extensive analytical capabilities and innovative process testing and modeling instrumentation. Using laboratory bench- and pilot-scale equipment, the group is able evaluate existing and newly developed water treatment technologies and to explore “what-if” scenarios under actual-use conditions. Process water quality can be synthesized, or the customer’s water can be brought to the laboratory for treatment evaluation. In either case, hard data and the insights gained from our extensive experience allow our field representatives to confidently provide well-documented treatment recommendations for addressing a multitude of customer challenges.

Notably, our facility in Wilmington, Delaware, contains pilot cooling towers equipped with corrosion sensors and fouling monitors that can be used to study biofilm and inorganic scale control using chemical and mechanical evaluation and treatment technologies. Our facilities in Mönchengladbach, Germany, and Shanghai, China, are also equipped with bench-scale corrosion and fouling monitoring technologies.

Testing and Modeling Capabilities

- Pilot cooling towers

- Spinner baths for corrosion inhibition screening

- Electrochemical tests for evaluation of corrosion treatment programs

- Recirculation systems for heat transfer scaling and corrosion studies

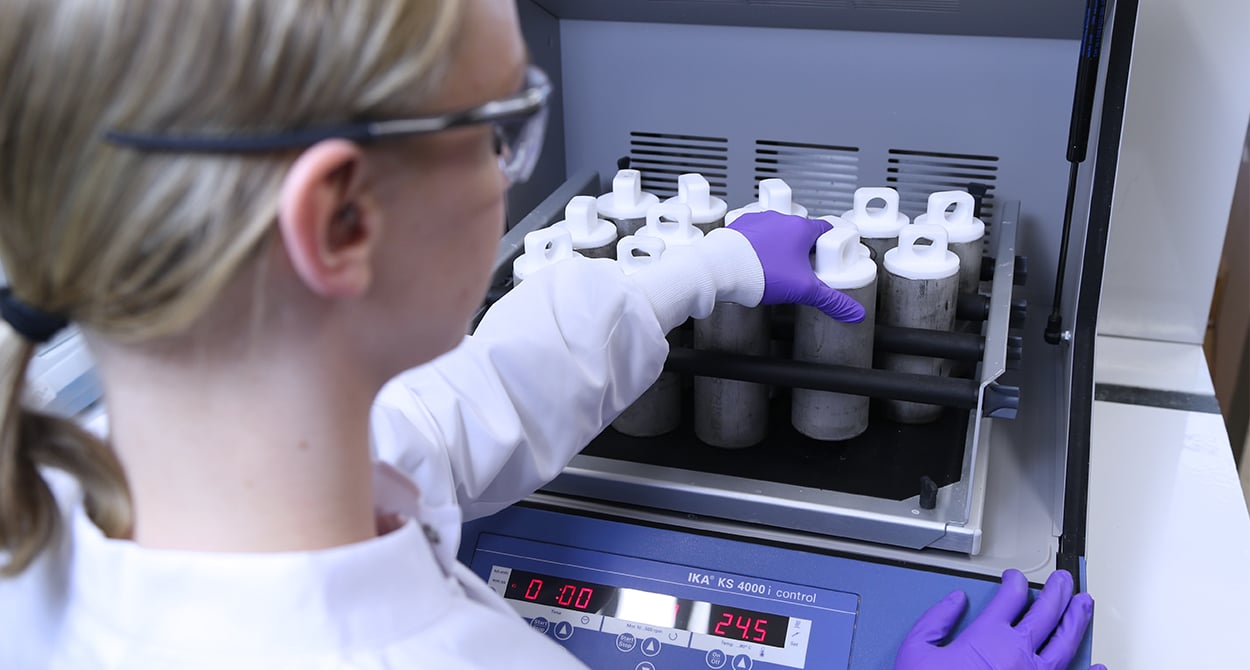

- Incubator shakers for antiscalant studies

- Capillary tube blocking monitor for antiscalant studies and process simulations such as open and once-through cooling systems and process circuits

- Pressurized autoclaves for evaluating thermal stability/decomposition products of treatments

- Flat sheet membrane unit for antiscalant screening for UF/RO membrane treatment

- Autoclave testing to mitigate corrosion and scale in food and beverage pasteurization processes for cans and crowns

- Test equipment for simulation of Dissolved Air Flotation (DAF) systems

- Filtration/drainage testing for wastewater clarification studies

- OnGuard™ analyzers for real-time detection of fouling and scaling

- Mareco* stamp presses for evaluation of solid/liquid separation

- Sieve tests with “high stress” stirring for simulation of centrifuge solid/liquid separation

- Simulation of sedimentation for mineral processing applications

- Contifoam* measuring device for automatic continuous foam-height measurement for defoamer studies

- Rheometers for measurement of yield stress/viscosity of mineral slurries

- Centrifuges for corn oil extraction aid product screening and liquid/liquid separation studies

- Multiple test methods for screening dust control products

Specialized Services

- Process and system audits

- Critical analyses, including water, deposits, microbiology, process streams and metallurgical composition/preservation

- Advanced feed and control systems

- Customized water and process treatment solutions

Cutting-Edge Technology Development

Over the years, the Water Applications Testing Services group has gained a great deal of expertise regarding the relative strengths and limitations of existing treatment technologies through real-world service to customers. This knowledge is transferred to our R&D team to support their development of advanced water treatment and process improvement technologies. Our scientists benchmark newly developed treatments against existing technology to maximize their performance and value, long before they reach the marketplace.