Over the past 30 years, the paper manufacturing industry has witnessed a significant level of change. Much of this change has been driven by the demand for fiber-based packaging materials in combination with a decline in the production of graphic paper. This has led to an increase in programs to convert graphic paper machines to packaging machines and there has also been a concurrent increase in the volume of material available for recycling mills. Layered over these challenges is a growing focus on circularity and sustainability, with the goal to limit the use of toxic chemicals and to divert waste from landfills.

Together, these trends have fueled efforts in the paper industry to improve the efficiency of fiber recycling systems to help meet the demand for packaging while also achieving economic and sustainability goals. This blog will review some of the challenges involved in fiber recycling and how solutions from Solenis can help.

Contaminants and Other Complications

Fiber recycling is key to increasing the sustainability and efficiency of the paper lifecycle. However, mills face a number of challenges when it comes to fiber recycling, from the quality and condition of recovered materials to contaminants that are introduced into the furnish. Let’s review three of the biggest obstacles encountered when working with recycled fiber.

- Chemically Treated Packaging

The current focus on sustainable fiber-based packaging aims to reduce the use of chemicals. However, sustainable solutions may not meet the demands for water and oil resistance needed for barrier coatings used in food packaging. From bakery and bread packaging, fast-food wraps, hot and cold drink cups, molded fiber food trays, and molded fiber packaging, these barrier properties are essential and often rely on undesired chemicals such as per- and polyfluoroalkyl substances (PFAS) and traditional plastic solutions.

These traditional options have disadvantages, such as over-engineering (i.e., elevated chemical dosages) for the functional end-use or ineffective recycling rates of the finished products.

- Contaminants

Research has shown that wood-based fibers can be recycled more than 25 times in ideal cases (Source: “Recyclability of Cartonboard and Carton” by Dr Rene Eckhart, Dec. 2021), but recycled fiber material comes with non-fiber contaminants or impurities, such as inks, stickies, glue, or barrier coatings. In addition, food packaging can contain food residuals. These contaminants affect many critical aspects of papermaking, including repulping and retention and formation processes. This in turn leads to efficiency issues and higher effluent load in wastewater.

- Quality and Consistency of Materials

The industry has seen an increase in the use of non-traditional fibers like straw, bamboo, grass fiber alternatives, and even bagasse, an agricultural waste stream fiber. The varied nature of the materials recovered makes stock preparation more difficult. At the same time, there is less virgin fiber material coming into the production stream. The quality of the fibers drops every time they are processed. As the amount of fresh fiber in the mix decreases, the overall recycled paper quality also decreases.

Paper mills must understand and consider each of these factors before they can fully take advantage of the increased stream of recovered paper and cardboard. The goal is to improve fiber retention and remove colloidal and dispersed contaminants, which improves the efficiency of the fiber recycling circuit. This requires a holistic approach that also considers water treatment solutions. A specialty chemical supplier with deep application expertise and real-world experience with paper machine conversions can be an invaluable partner in developing fiber recycling solutions.

Process, Product, People

Solenis brings together a powerful combination of innovative products, process understanding, and technical expertise to help papermakers optimize fiber yield, energy, processability, water usage, and effluent water load. Our broad product portfolio includes a range of process chemicals to improve the operational efficiency of fiber treatment by enabling a higher fiber yield and reclamation of more virgin-origin fibers from recycled packaging. Our key chemistries include:

- Repulping Aids. Solenis repulping aids allow more energy-efficient repulping in fiber recycling, including repulping of wet strength-containing grades. Repulping aids can improve recycled fiber disintegration, thereby increasing fiber yield and aligning pulper throughput with paper machine production.

- Contaminant Control Agents. Solenis contaminant control options help reduce the burden of foreign materials entering the recycling stream. These include Zenix™ and DeTac™ detackifiers, Praestafix™ fixatives, and Zenix™ surface passivation technologies. Laboratory application testing, including charge, turbidity, and quantification of hydrophobic particles and the nature of contaminants, will define the best contaminant control treatment options and is backed up with analytical tools to identify and quantify the level of incoming contaminants.

- Retention Aids. Solenis retention and drainage aids improve retention, self-retention, and dewatering. PerForm™, Percol™, and the total dewatering program offer sustainable benefits to our customers, such as dryer section energy, fiber, and water savings.

- Starch Management Programs. The Biobond SM program helps mills producing recycled paperboard handle the challenges associated with the starch content from the incoming recycled paper and board. The dissolved starch in the papermaking system can negatively affect microbial activity, pH, conductivity, and the performance of other functional and chemical process aids, as well as effluent treatment costs. The Biobond program retains and preserves starch from the wastepaper in its active form, thereby delivering improved yield, strength, and chemical treatment effects and minimizing the need for effluent treatment.

- Strength Additives. These additives allow papermakers to manage the required wet and dry strength characteristics of their products. In regard to recycled paper this is important to provide consistent quality in paper strength. Solenis offers a wide portfolio of strength additives and programs, including Hercobond™ polyvinylamine (PVAm) and Hercobond Plus glyoxylated polyacrylamide (GPAM) chemistries, as well as FusionSM combined strength and retention-drainage polymer program.

- Barrier Coatings. Solenis’ TopScreen™ barrier coatings enable papermakers to produce polyethylene-free, environmentally friendly, paper packaging. TopScreen products can be engineered to deliver varying degrees of oil and grease resistance, water repellency, water vapor transmission rate (WVTR), and heat sealability. And all TopScreen products enable the production of repulpable, recyclable, and often compostable fiber-based articles.

In addition to this diverse product portfolio, Solenis offers extensive laboratory support and testing services to help customers develop an optimized solution for handling recycled material coming into the paper and board streams. For example, our experts can evaluate the repulping and recycling efficiency of varied materials, including barrier- and surface-treated material, according to established and harmonized industry test standards such as those established by Western Michigan University (WMU) and the Confederation of European Paper Industries (CEPI). The testing focuses on the initial repulping rate, establishing the mass balance of accept/reject and loss fractions, defining colloidal dissolved material, and evaluating the sheet aspect (optical, dirt count, and strength properties) upon recycling.

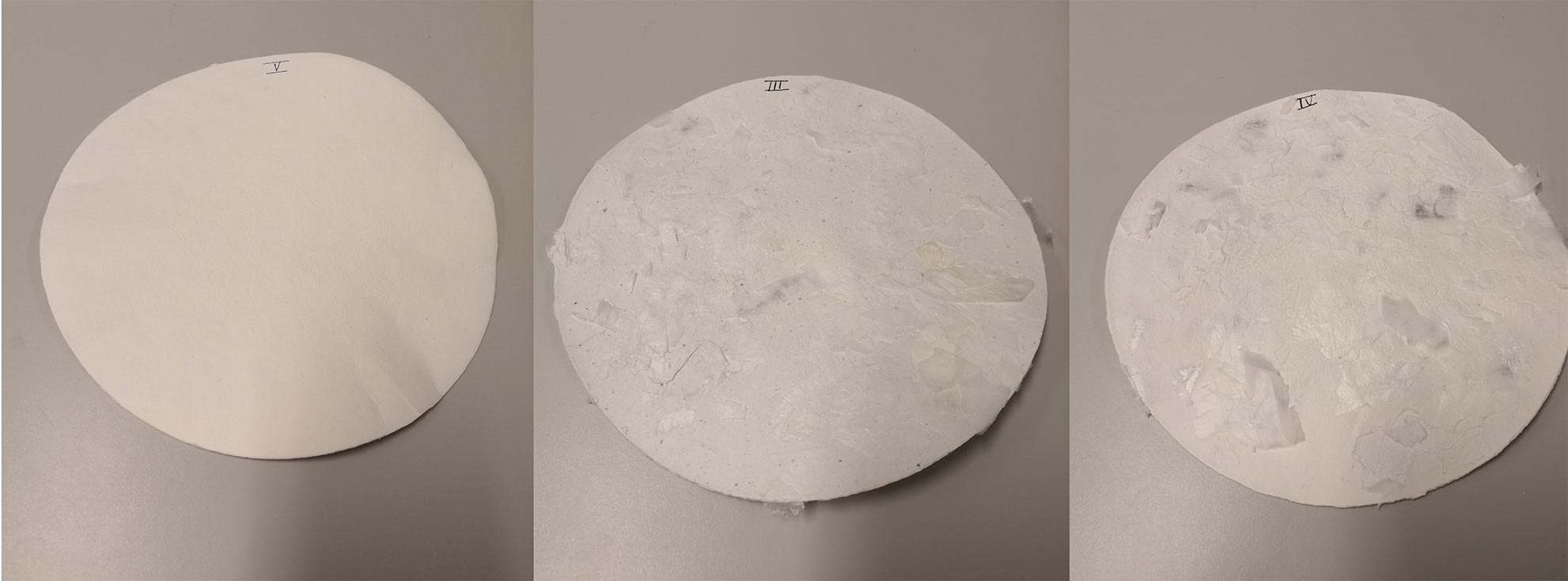

Figure 1: left TopScreen barrier coating, middle PLA laminated paper, right PE laminated paper

Solenis also uses analytical tools — such as the Dynamic Sheet Former and our pilot paper machine — and offers extensive paper testing capabilities to qualify the strength of incoming recycled fibers and to forward recommendations for dry strength programs to compensate for the loss of fiber strength and basis weight reduction, enabling a higher proportion of recovered fiber usage.

Your Recycled Fiber Partner

While fiber recycling programs can help meet the increased demand for cardboard packaging, mills must be able to adapt their operations to overcome a number of challenges, from contamination to inefficient energy and water usage. Innovative solutions from Solenis offer a promising path toward more efficient systems and sustainable fiber recycling programs.

As the trusted solutions provider for the pulp and paper industry, Solenis has the market and application knowledge and laboratory capabilities to develop tailored solutions and tackle any challenges that our customers may be facing.

Contact a Solenis expert today to learn how we can help with your fiber recycling challenges.